Can Smart Toilets Really Catch Fire?

5 Core Technologies That Eliminate Fire Risks

Smart toilets have revolutionized bathroom comfort and hygiene. But are they truly safe? Especially when it comes to fire risks, the answer depends on the technology behind the product.

In 2023, a European supplier recalled four brands after smoke was detected during a 55°C heat test. That incident raised concerns worldwide.

At HTD, our solution goes far beyond compliance — our UL94 V-0 certified seat withstood 232°C for 120 seconds without ignition. With over 120,000 units shipped and zero combustion cases, HTD sets a new benchmark in smart toilet safety.

Table of Contents

- 1. The Pyramid of Material Flame Resistance

- 2. Armored Circuit Protection System

- 3. Intelligent Overload Protection

- 4. Extreme Condition Simulations

- 5. Full Traceability System

- Conclusion: Fire-Safe Innovation Built In

- FAQ: Smart Toilet Fire Safety

1. The Pyramid of Material Flame Resistance

Material is the first line of defense. Most conventional brands use low-cost PP plastic. HTD adopts a flame-resistant ABS+POM composite that’s 9× more fire-resistant.

| Test Criteria | Industry Standard | HTD Standard | Data Source |

|---|---|---|---|

| Instant Heat Resistance | 150°C for 60s | 232°C for 120s | GB/T34549 |

| Flame Spread Speed | 30mm/min | 0mm/min | Lab Test |

| Material Decay (Annually) | 12% | ≤1.8% | 5-Yr Tracking |

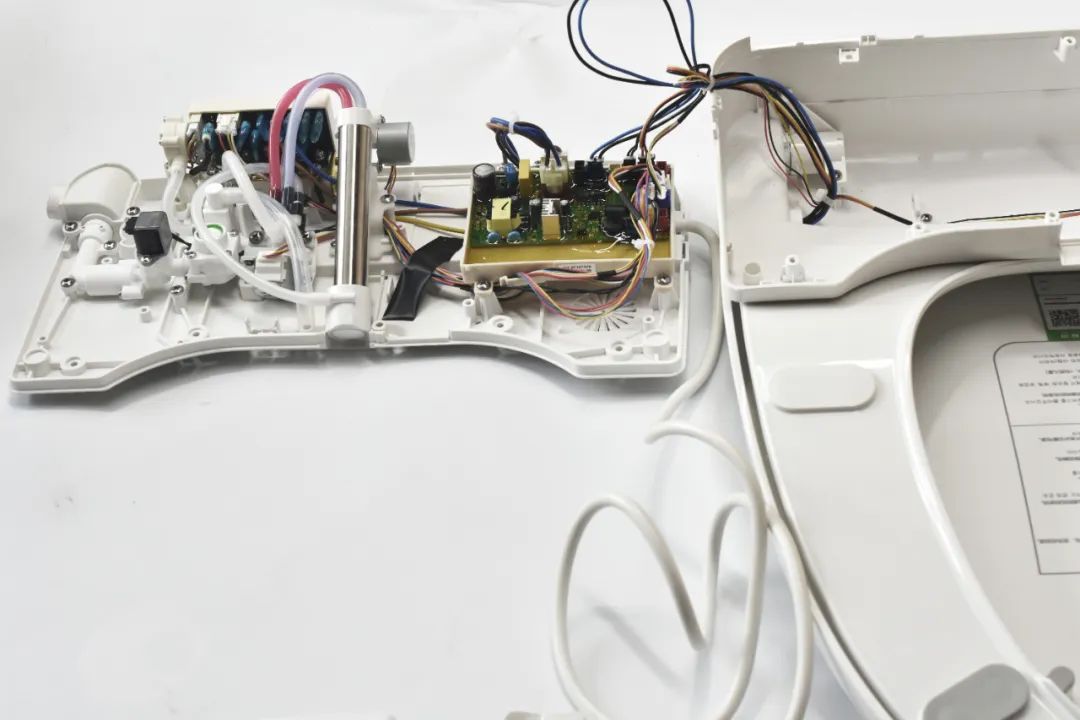

2. Armored Circuit Protection System

Bathrooms are humid, and electronic circuits are vulnerable. That’s why our PCBs are over-engineered for safety.

| Risk Scenario | Common Solution | HTD Solution | Verification Test |

|---|---|---|---|

| High Humidity | Basic coating | IPX5 Full Epoxy Potting | Water immersion test |

| Voltage Spikes | 2.5mm Air Gap | 4mm Air Gap + EMI Shield | 6000V withstand surge |

| Corrosion | PVC Insulation | 3-Layer Ceramic Coating | 5000hr Salt Spray |

4. Extreme Condition Simulations

We simulate 15 real-world failure scenarios to ensure reliability under stress:

- Child activates heater: Auto shut-off in 10 minutes

- Nozzle blockage: 35kPa pressure release valve

- Monsoon condensation: Nano waterproof coating

Result: HTD: 0.3% failure rate | Other brands: Up to 17%

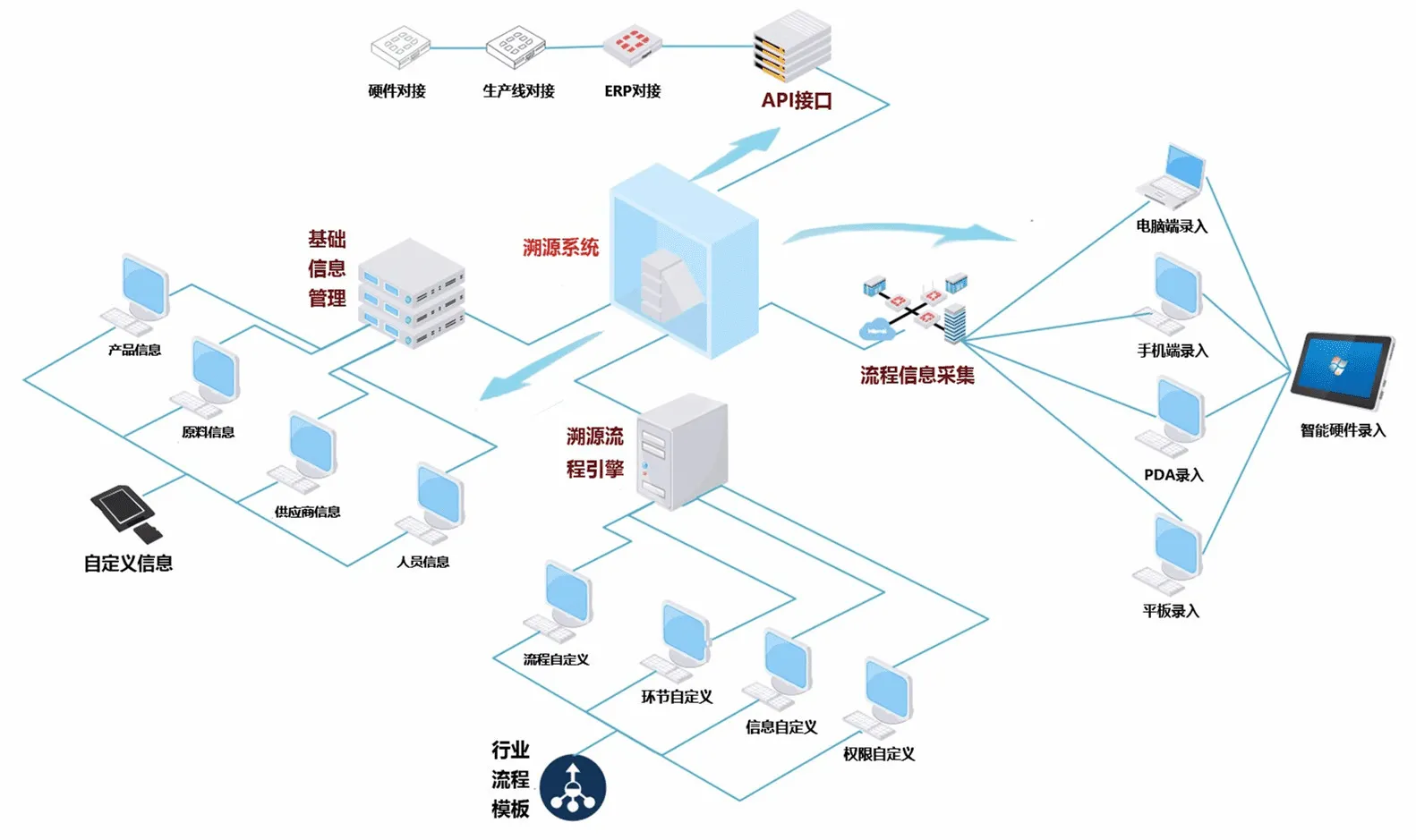

5. Full Traceability System

From production to delivery, HTD ensures complete transparency and quality control.

- 10-year material sample archive

- Laser-etched PCB serial tracking

- Daily temperature/current testing in our on-site lab

2023 Units Shipped: 120,000

Fire or Overheat Cases: 0

Conclusion: Fire-Safe Innovation Built In

Smart toilets can pose a fire hazard — if they’re built with substandard materials or poor oversight. HTD uses 22 patented technologies to build five defensive layers into every unit.

From heat-resistant materials to real-time monitoring, we’ve engineered safety at every level. That’s why procurement managers around the world trust HTD for both performance and peace of mind.

FAQ: Smart Toilet Fire Safety

Q1: Can a smart toilet overheat?

Only if it’s poorly designed. HTD models use dual sensors to auto-cutoff when necessary.

Q2: What certifications should I look for?

UL94 V-0 for materials, IEC/UL for electronics, and third-party surge test reports are essential.

Q3: Do I need special wiring for HTD units?

No. Standard bathroom wiring works. Our models handle voltage fluctuations internally.

Q4: Can HTD toilets handle high humidity?

Yes. Every PCB is IPX5 sealed and nano-coated to resist condensation and water ingress.

Q5: How do I verify safety claims?

Ask for our third-party lab reports and long-term reliability test data. We’re transparent.

📞 Ready to Learn More?

- Technical safety datasheets

- Lab certifications

- OEM/ODM collaboration details

✅ Safety doesn’t happen by accident — it’s built into every detail of an HTD smart toilet.