QUALITY ASSURANCE

Smart Toilet Solution Provider R&D and Production

CORE COMPONENTS WORKSHOP

The capability to independently innovate across core components—including toilet flushing systems,

heating elements, circuit boards, and electromagnetic valves—enables us to offer deep customization, maintain precise cost control,

and ensure consistent source-level quality.

Auto solenoid valve workshop

SMT

Injection workshop

Mold processing center

Machining center

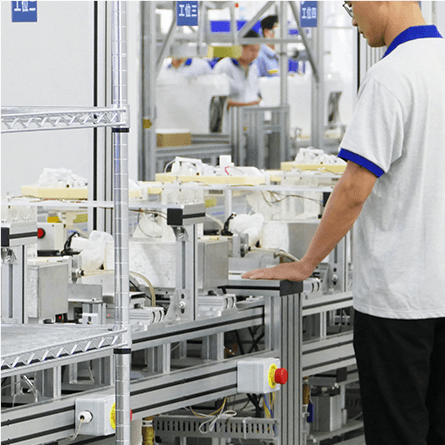

Automatic smart toilet production line

STRICT QUALITY CONTROL

We provide 100% inspection and testing from raw material, whole production process and finished products.

We always insist on high quality can save more cost for our partners and win more market,

win-win cooperation.

RAW MATERIAL ASSEMBLY AND TEST

Reversing valve, Pressure regulator valve, instaneous components, Instant hot components, cleaning

component and pulse valve assembly and test.

Base parts assembly and performance test

Water temperature, wind temperature, water flow, safety test

Smart toilet seat assembly & test

Functional test of smart toilet seat

Smart toilet integrated assembly and test

Performance testing: flush performance and functional testing, finally packing